Technical Data

|

Model |

HZ560DJK |

|

Pre-milling power |

1.8kw*2 |

|

Pre-milling motor for L shape |

4kw |

|

Ending trimming power |

0.37kw*2 |

|

Rough trimming power |

0.75kw*2 |

|

Fine trimming power |

0.75kw*2 |

|

Corner rounding power |

0.37kw*2 |

|

Feeding power |

3.7kw |

|

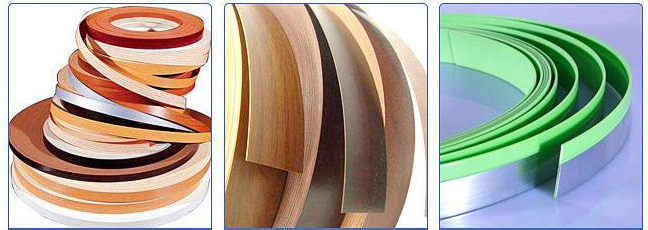

Edge band thickness |

0.4-3mm |

|

Edge band Max. width |

60mm |

|

Min length of workpiece |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.7Mpa |

|

Total power |

19.78kw |

|

Overall dimension |

9400*900*1600mm |

|

Weight |

3000kg |

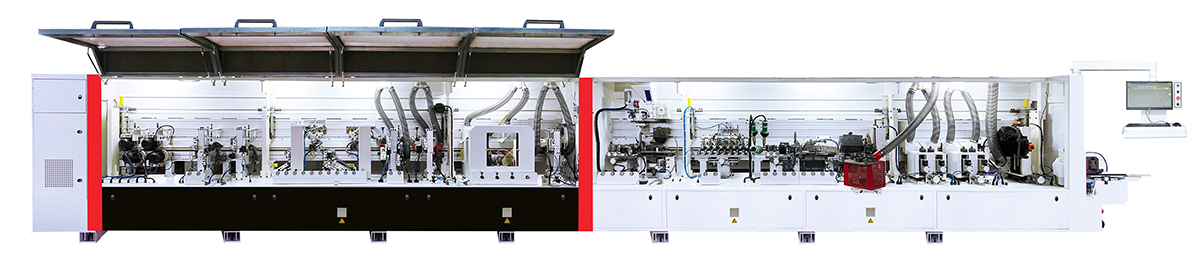

Function

1. Touch screen: Delta Touch screen makes your job easier.

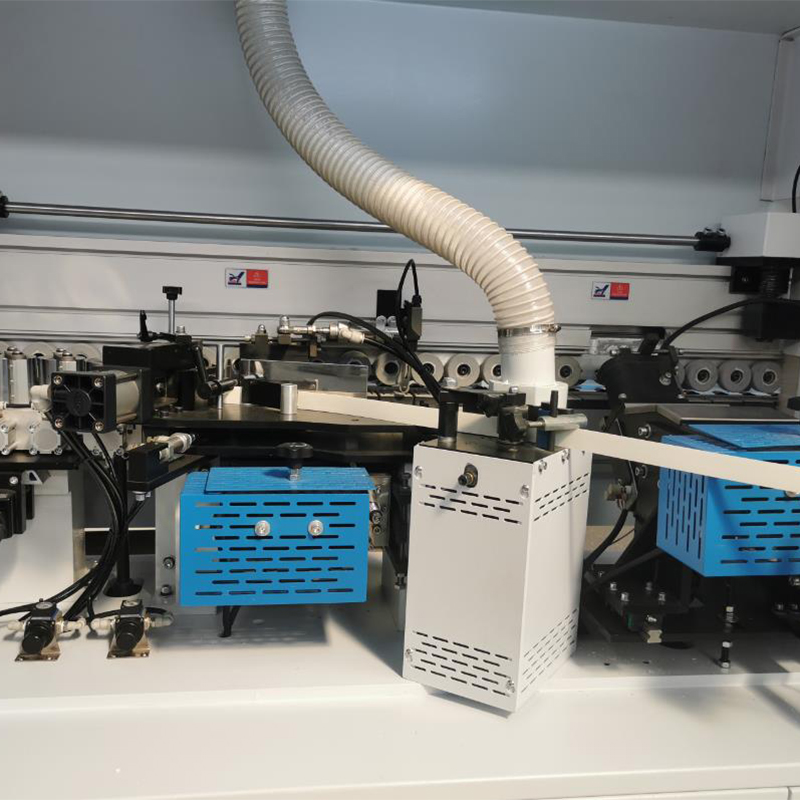

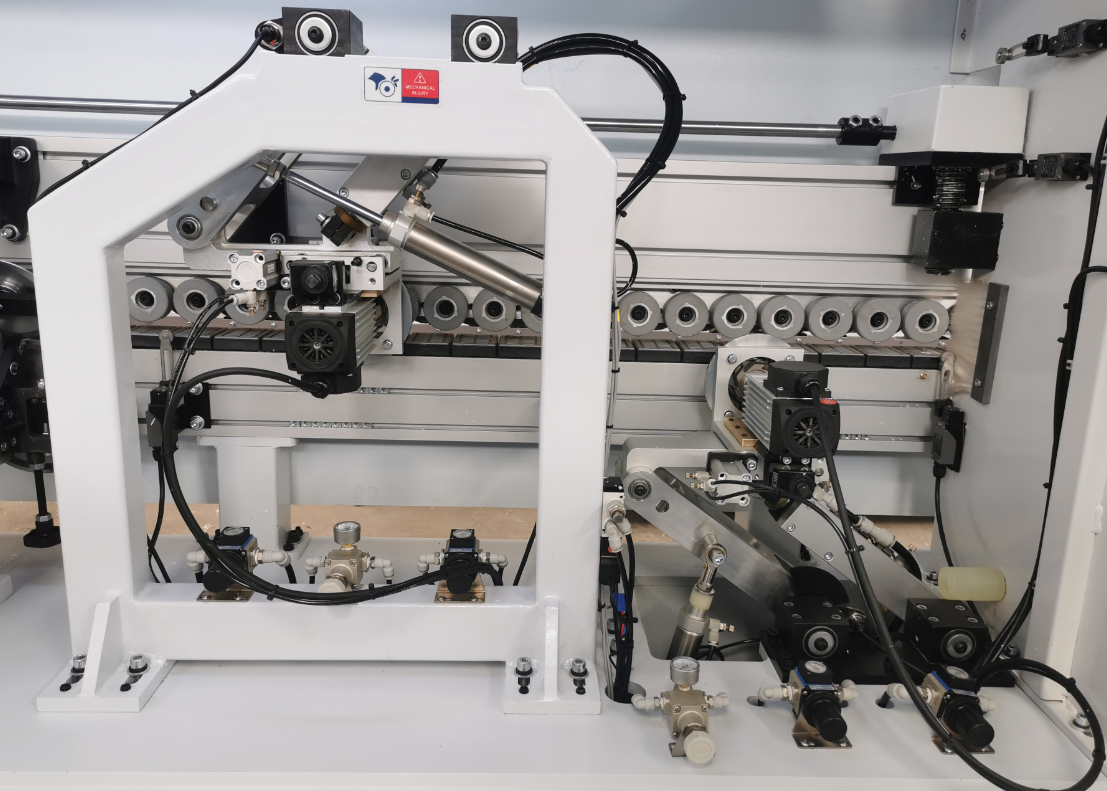

2. Glue tank group: It has two glue tanks. One is for coating straight surface of boards and the other is for coating bevel of boards. It is designed a special structure to coat adhesive on edge band and boards uniformly. They can bond together firmly.

3. Pre-milling group: It has double milling units. One is for milling straight surface of boards and the other It is for milling bevel of boards.

4. Heater: It is for heating edge band.

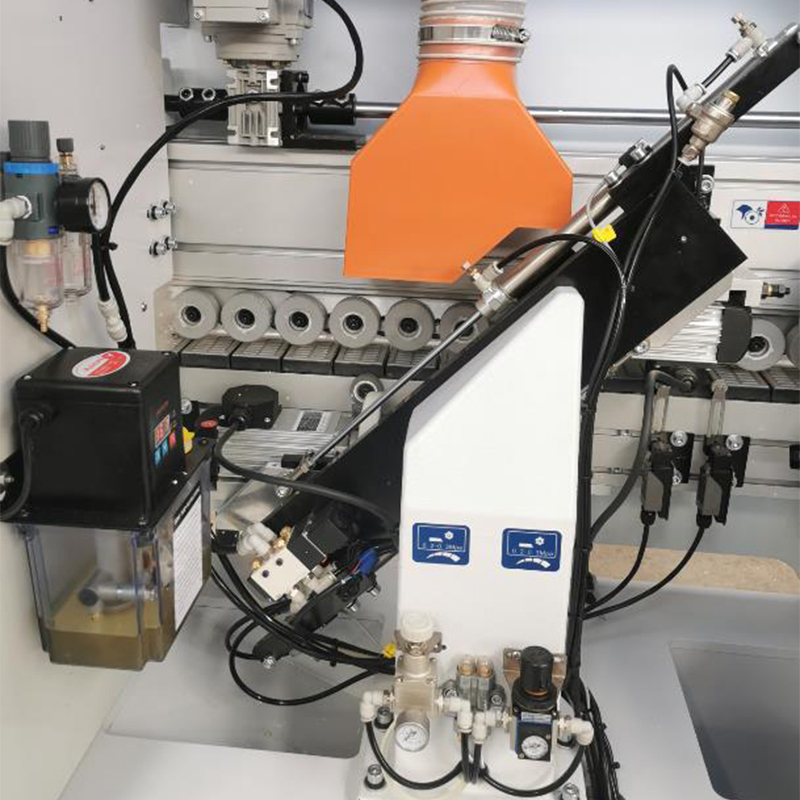

5. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors ensure the surface of edge band smooth after cutting.

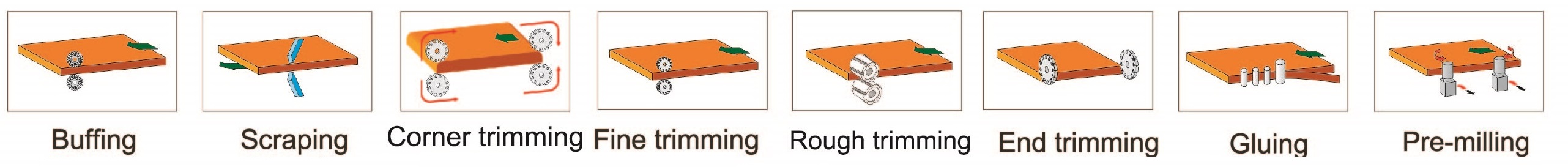

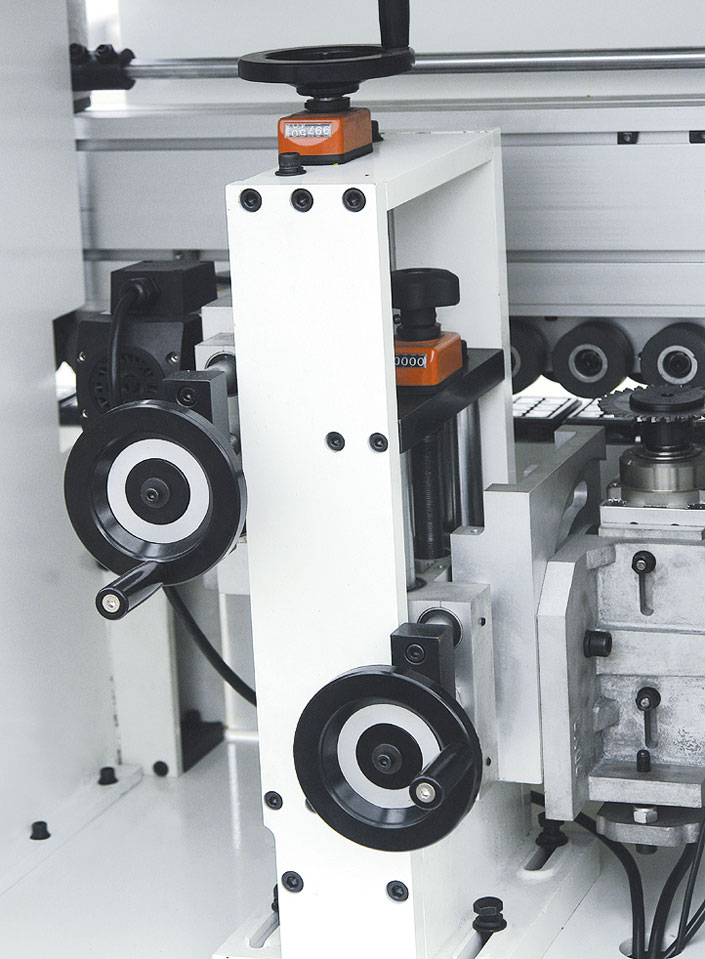

6. Rough trimming group: It has two individual high- frequency motors and can trim the exceeding edge on the board roughly.

7. Fine trimming group: It has two individual high- frequency motors and can trim the exceeding edge on the boards . It makes R2 on surface of edge band.

8. Corner trimming group: It makes corner of board smooth and beautiful.

9. Scraping Group: It makes the surface perfect finishing after the borads be scraped

10. Flat scraping group: It can clean extra adhesive on the board

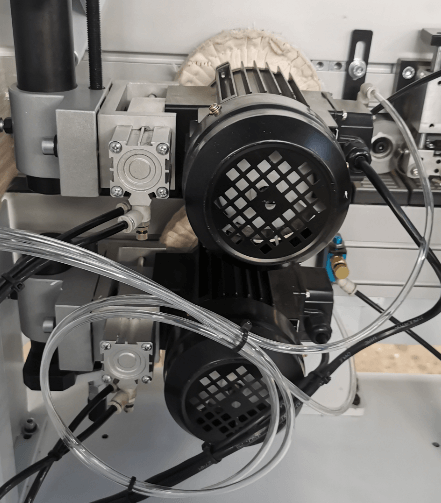

11. Double Buffing groups: It has four polishing wheels and four motors. The edge of board is very mooth after the boards are polished.

12. Hogging: Make a straight groove on the bottom or top of boards .

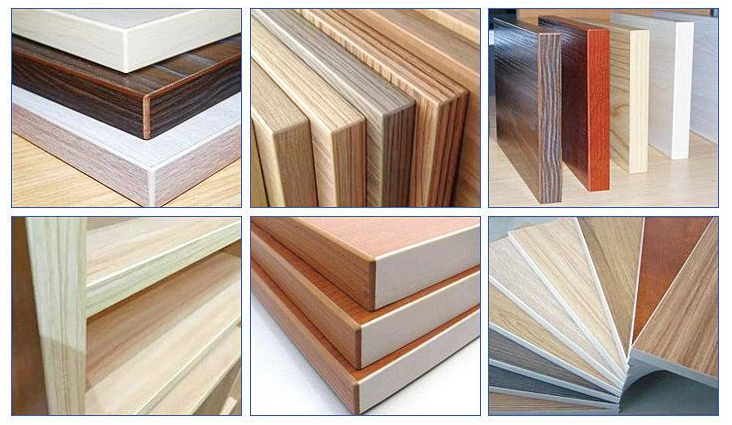

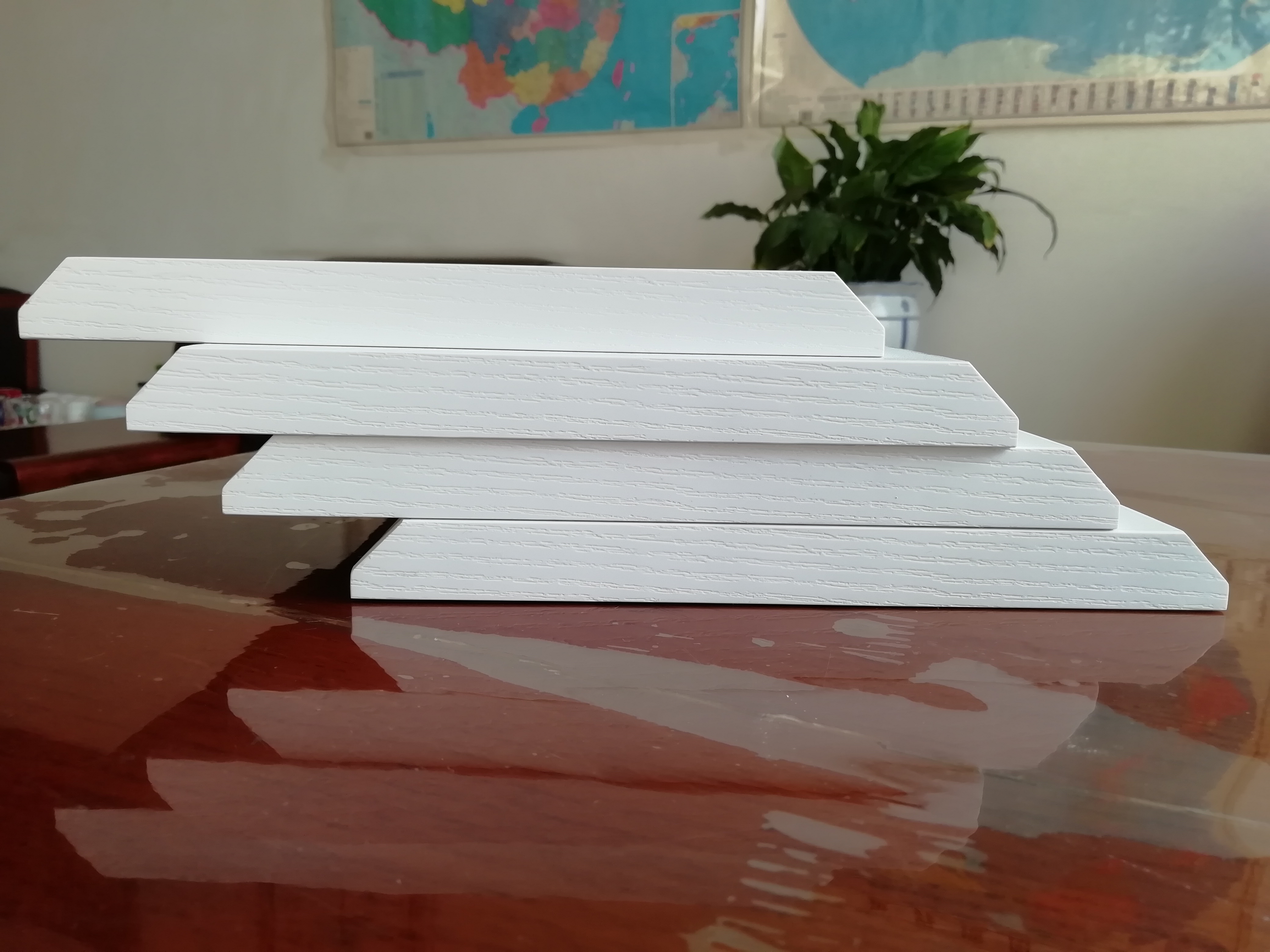

Material Photo

Finish Prouct Photo

Factory Photo