OEM/ODM Manufacturer Manual Edge Banding Cutter - Automatic edge banding machine with pre-milling and hogging HZ450DJK – Golden Detail:

Functions

The automatic edge bander machine is applying to the linear sealing of PVC, wood strip and veneer etc.

● The edge bander is heavy, strong and durable service.

● High efficiency and accuracy.

● Using imported engines and electric components.

● The pressing system of automatic edge banding machine is controlled by electrical switch. It works easily.

Technical Data

|

Model |

HZ450DJK |

|

Edgeband thickness |

0.4-3mm |

|

Edgeband width |

10-60mm |

|

Panel min. width |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.8Mpa |

|

Total power |

17.4kw |

|

Overall dimension |

6800X1100X1600mm |

|

Weight |

2800kg |

Function

1. Touch screen: Touch screen is Delta brand and it makes your work easier.

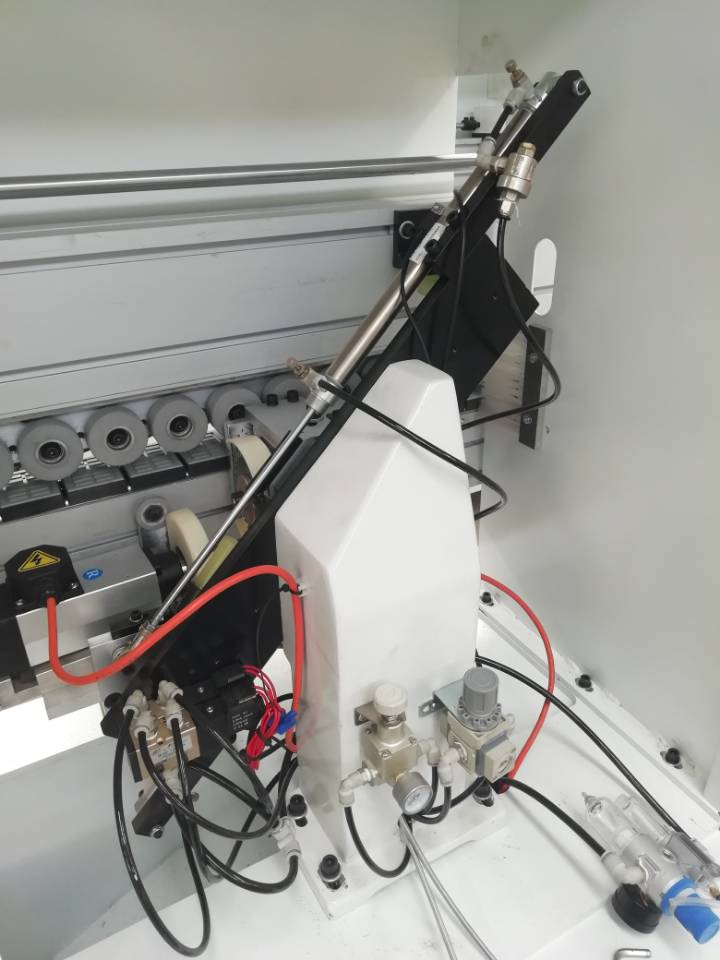

2. Pre-milling group: It has two trim-blades to make the edge of rough panels flatter so that panels edge be coated glue evenly.

3. Glue tank: It can coat adhesive on edge band and boards uniformly because it is designed a special structure . Edge band and boards can bond together firmly.

4. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors can make the surface of edge band smooth.

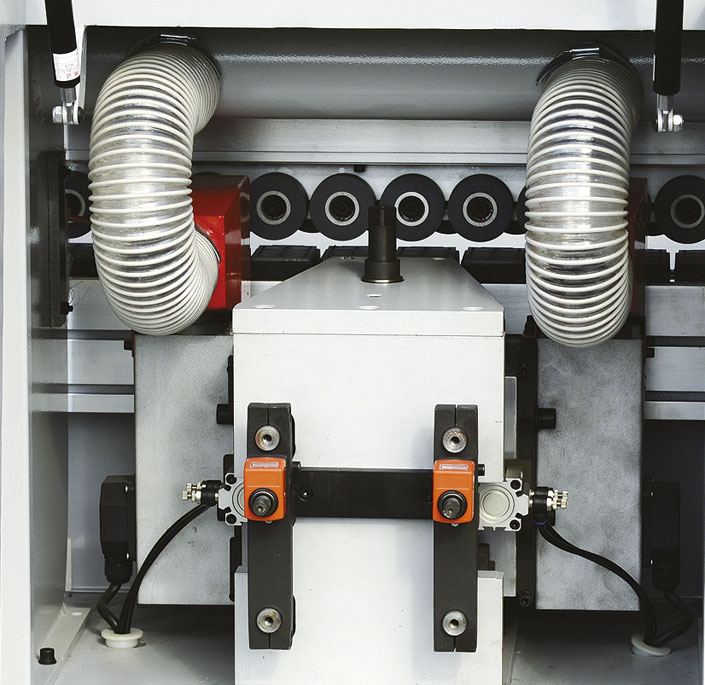

5. Rough trimming group: It can trim the exceeding edge on the panel roughly. It has double individual high- frequency motors.

6. Fine trimming group: It has two individual high- frequency motors and automatic tracking devices. It can make R2 on surface of edge band.

7. Corner trimming group: It makes corner of panels smooth and beautiful.

8. Scraping Group: It makes the surface perfect finishing after the borads be scraped

9. Hogging: Make a straight groove on the bottom or top of boards .

10. Buffing group: The edge of board is very smooth after the boards are polished. It has two polishing wheels and two motors.

Material Photo

Finish Prouct Photo

Factory Photo

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for OEM/ODM Manufacturer Manual Edge Banding Cutter - Automatic edge banding machine with pre-milling and hogging HZ450DJK – Golden, The product will supply to all over the world, such as: Johor, New Zealand, Puerto Rico, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our solutions are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

-

Factory Price Curved Edge Bander - Automatic e...

-

Super Lowest Price Curve Edge Bander - Chinese...

-

New Arrival China Machine Edge Banding - Chine...

-

Excellent Quality Cutting Large Panels On Table...

-

Top Suppliers Hand Held Edge Bander - Chinese ...

-

OEM China Small Sliding Table Saw - Electronic...