OEM Supply Plywood Edgebander - Automatic edge banding machine with pre-milling and hogging HZ450DJK – Golden Detail:

Functions

The automatic edge bander machine is applying to the linear sealing of PVC, wood strip and veneer etc.

● The edge bander is heavy, strong and durable service.

● High efficiency and accuracy.

● Using imported engines and electric components.

● The pressing system of automatic edge banding machine is controlled by electrical switch. It works easily.

Technical Data

|

Model |

HZ450DJK |

|

Edgeband thickness |

0.4-3mm |

|

Edgeband width |

10-60mm |

|

Panel min. width |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.8Mpa |

|

Total power |

17.4kw |

|

Overall dimension |

6800X1100X1600mm |

|

Weight |

2800kg |

Function

1. Touch screen: Touch screen is Delta brand and it makes your work easier.

2. Pre-milling group: It has two trim-blades to make the edge of rough panels flatter so that panels edge be coated glue evenly.

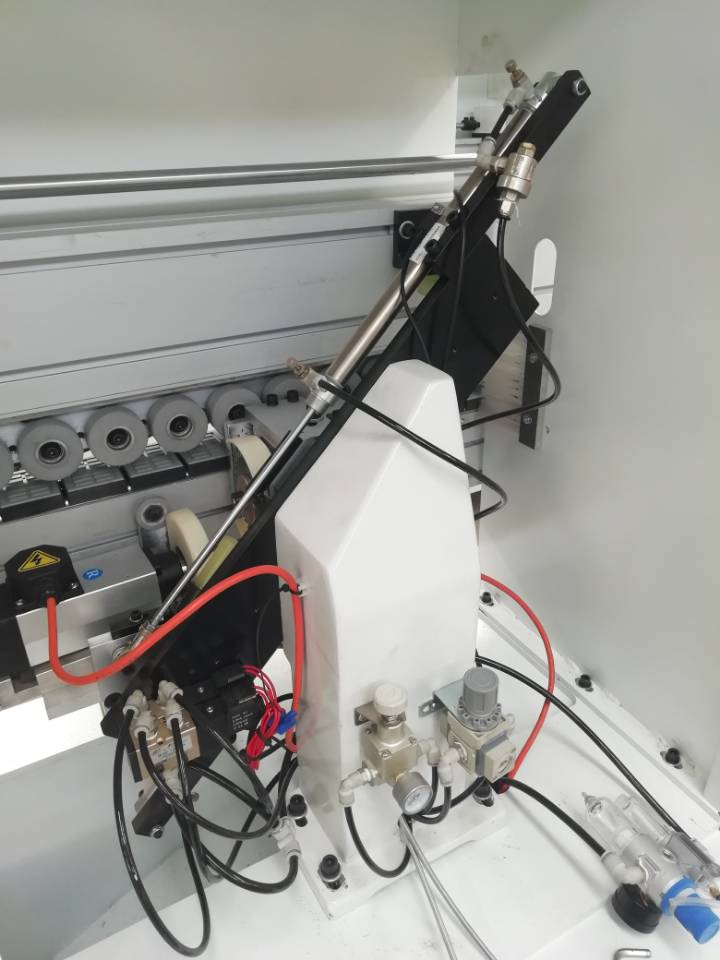

3. Glue tank: It can coat adhesive on edge band and boards uniformly because it is designed a special structure . Edge band and boards can bond together firmly.

4. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors can make the surface of edge band smooth.

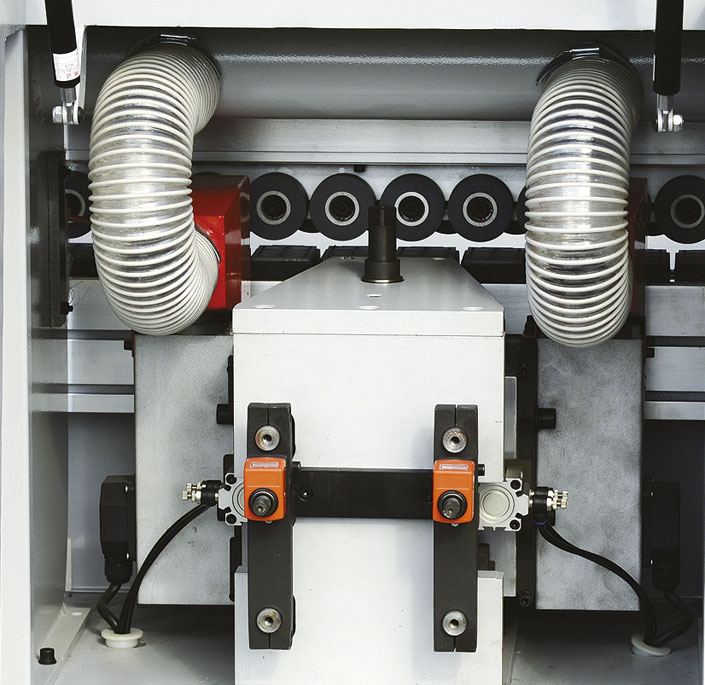

5. Rough trimming group: It can trim the exceeding edge on the panel roughly. It has double individual high- frequency motors.

6. Fine trimming group: It has two individual high- frequency motors and automatic tracking devices. It can make R2 on surface of edge band.

7. Corner trimming group: It makes corner of panels smooth and beautiful.

8. Scraping Group: It makes the surface perfect finishing after the borads be scraped

9. Hogging: Make a straight groove on the bottom or top of boards .

10. Buffing group: The edge of board is very smooth after the boards are polished. It has two polishing wheels and two motors.

Material Photo

Finish Prouct Photo

Factory Photo

Product detail pictures:

Related Product Guide:

Sticking towards the principle of "Super High-quality, Satisfactory service" ,We've been striving to become a superb business partner of you for OEM Supply Plywood Edgebander - Automatic edge banding machine with pre-milling and hogging HZ450DJK – Golden, The product will supply to all over the world, such as: Ecuador, Haiti, Southampton, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.