Low MOQ For Scm K360 Edgebander - Bevel and straight edge bander HZ560DJK – Golden Detail:

Technical Data

|

Model |

HZ560DJK |

|

Pre-milling power |

1.8kw*2 |

|

Pre-milling motor for L shape |

4kw |

|

Ending trimming power |

0.37kw*2 |

|

Rough trimming power |

0.75kw*2 |

|

Fine trimming power |

0.75kw*2 |

|

Corner rounding power |

0.37kw*2 |

|

Feeding power |

3.7kw |

|

Edge band thickness |

0.4-3mm |

|

Edge band Max. width |

60mm |

|

Min length of workpiece |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.7Mpa |

|

Total power |

19.78kw |

|

Overall dimension |

9400*900*1600mm |

|

Weight |

3000kg |

Function

1. Touch screen: Delta Touch screen makes your job easier.

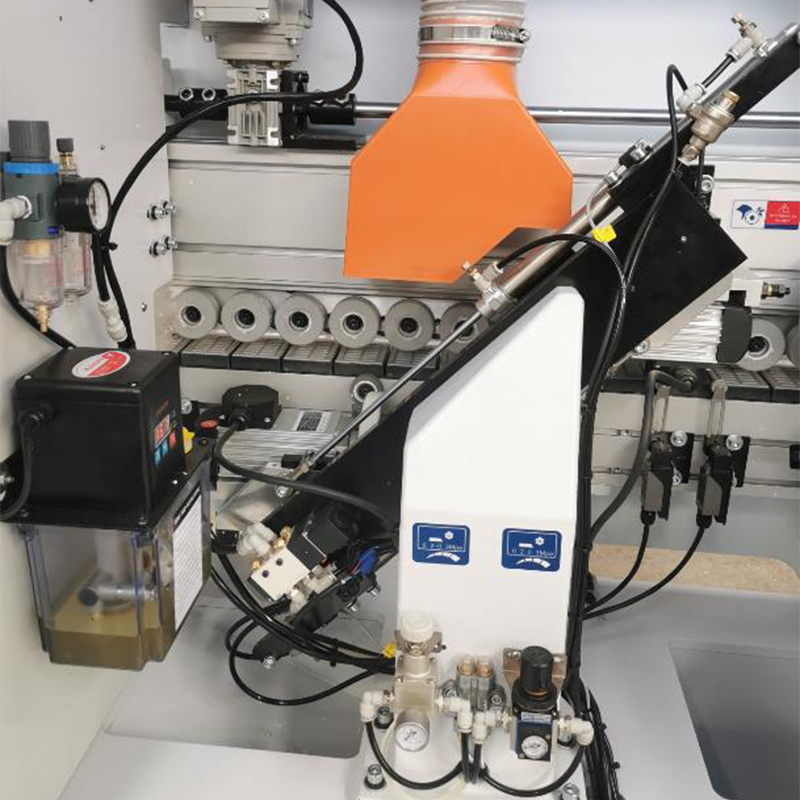

2. Glue tank group: It has two glue tanks. One is for coating straight surface of boards and the other is for coating bevel of boards. It is designed a special structure to coat adhesive on edge band and boards uniformly. They can bond together firmly.

3. Pre-milling group: It has double milling units. One is for milling straight surface of boards and the other It is for milling bevel of boards.

4. Heater: It is for heating edge band.

5. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors ensure the surface of edge band smooth after cutting.

6. Rough trimming group: It has two individual high- frequency motors and can trim the exceeding edge on the board roughly.

7. Fine trimming group: It has two individual high- frequency motors and can trim the exceeding edge on the boards . It makes R2 on surface of edge band.

8. Corner trimming group: It makes corner of board smooth and beautiful.

9. Scraping Group: It makes the surface perfect finishing after the borads be scraped

10. Flat scraping group: It can clean extra adhesive on the board

11. Double Buffing groups: It has four polishing wheels and four motors. The edge of board is very mooth after the boards are polished.

12. Hogging: Make a straight groove on the bottom or top of boards .

Material Photo

Finish Prouct Photo

Factory Photo

Product detail pictures:

Related Product Guide:

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for Low MOQ For Scm K360 Edgebander - Bevel and straight edge bander HZ560DJK – Golden, The product will supply to all over the world, such as: Birmingham, Ottawa, Rio de Janeiro, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

-

New Arrival China 3hp Table Saw - Electronic C...

-

Factory Wholesale Automated Table Saw - Semi-a...

-

Big Discount Bander Machine - Semi-automatic B...

-

Free Sample For Folding Table Saw - Electronic...

-

Cheap PriceList For Maual Edge Sealing Machine ...

-

Reasonable Price Automatic Table Saw Fence - S...