Big Discounting Jet Edge Bander - Automatic edge banding machine with pre-milling and hogging HZ450DJK – Golden Detail:

Functions

The automatic edge bander machine is applying to the linear sealing of PVC, wood strip and veneer etc.

● The edge bander is heavy, strong and durable service.

● High efficiency and accuracy.

● Using imported engines and electric components.

● The pressing system of automatic edge banding machine is controlled by electrical switch. It works easily.

Technical Data

|

Model |

HZ450DJK |

|

Edgeband thickness |

0.4-3mm |

|

Edgeband width |

10-60mm |

|

Panel min. width |

80mm |

|

Feeding speed |

12-20m/min |

|

Air pressure |

0.8Mpa |

|

Total power |

17.4kw |

|

Overall dimension |

6800X1100X1600mm |

|

Weight |

2800kg |

Function

1. Touch screen: Touch screen is Delta brand and it makes your work easier.

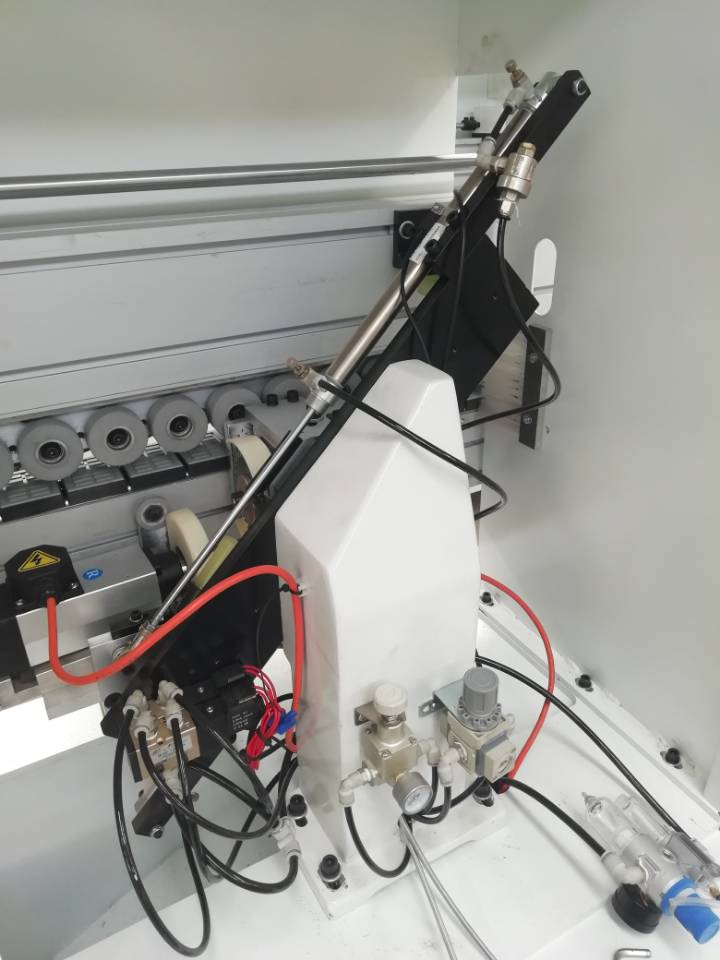

2. Pre-milling group: It has two trim-blades to make the edge of rough panels flatter so that panels edge be coated glue evenly.

3. Glue tank: It can coat adhesive on edge band and boards uniformly because it is designed a special structure . Edge band and boards can bond together firmly.

4. End trimming group: It works by a precise guide track movement. The structure of automatic tracking and high -frequency motors can make the surface of edge band smooth.

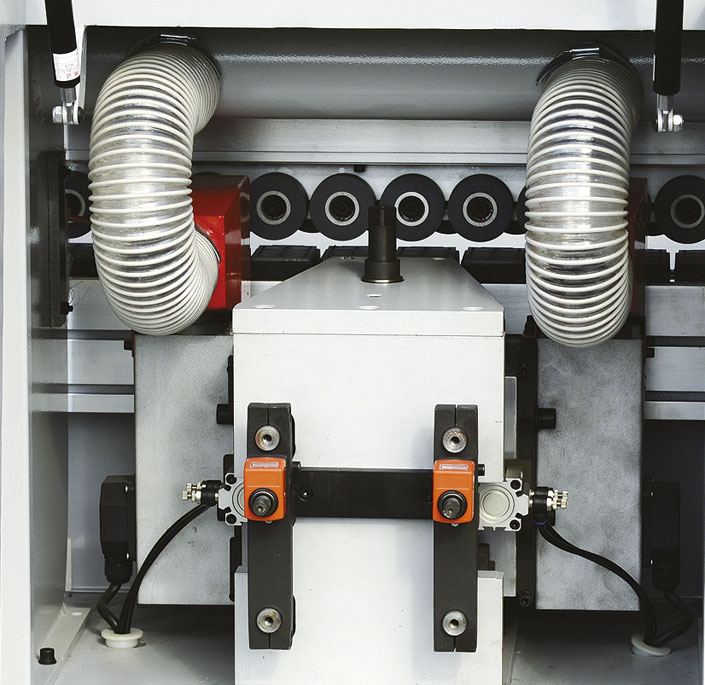

5. Rough trimming group: It can trim the exceeding edge on the panel roughly. It has double individual high- frequency motors.

6. Fine trimming group: It has two individual high- frequency motors and automatic tracking devices. It can make R2 on surface of edge band.

7. Corner trimming group: It makes corner of panels smooth and beautiful.

8. Scraping Group: It makes the surface perfect finishing after the borads be scraped

9. Hogging: Make a straight groove on the bottom or top of boards .

10. Buffing group: The edge of board is very smooth after the boards are polished. It has two polishing wheels and two motors.

Material Photo

Finish Prouct Photo

Factory Photo

Product detail pictures:

Related Product Guide:

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for Big Discounting Jet Edge Bander - Automatic edge banding machine with pre-milling and hogging HZ450DJK – Golden, The product will supply to all over the world, such as: Haiti, Grenada, Saudi Arabia, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

-

Rapid Delivery For Small Edgebander Machine - ...

-

Factory Made Hot-Sale Table Saw For Woodworking...

-

Manufacturing Companies For Edge Band Cutting M...

-

Factory Cheap Hot Sliding Panel Table Saw - Du...

-

Cheapest Price Edge Banding Machine For Plywood...

-

Wholesale Price China Professional Table Saw -...